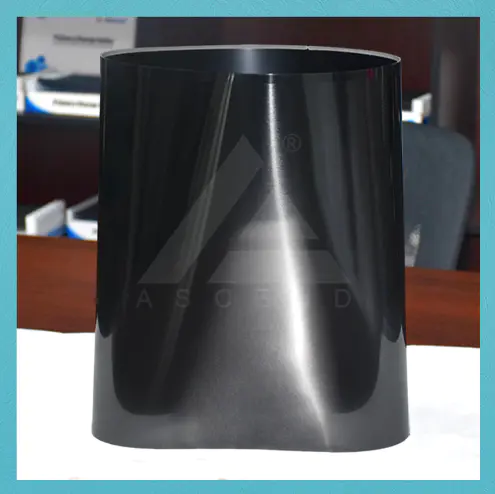

Fuser film sleeve

The composition of toner and process is introduced

by:Ascend

2020-05-02

Of toner, mainly including (

bāo kuò)

The resin, carbon black, magnetic oxygen (

氧气)

(

氧化)

Iron particles, charge control, lubricant, hot melt plastic, specific role is as follows: resin (

Resin)

—

—

The main imaging material, constitute the main body of carbon powder;

Carbon (

C)

Black -

—

Main imaging material, have the ability to adjust the color depth of magnetic iron oxide -

—

Under the magnetic attraction of the magnetic roller, portable powdered carbon adsorption on the magnetic roller;

Charge control (

控制)

Particles -

—

Controlling carbon powder charge make carbon powder charged even after the friction;

Lubricant (

Effect: can reduce or avoid friction and wear)

(

Silicon)

—

—

Lubrication, and at the same time control friction charge;

Hot melt plastics (

Structure: synthetic resin, plasticizer, stabilizer, pigment)

(

Plasticizer)

—

—

Controlling carbon powder melting point, carrying carbon powder in melt state infiltration of paper fibers, form a strong image.

Color is used in the paper in the laser printer toner fixing powder material.

Black toner by bonding resin, carbon black, electronic agents, additives such as ingredients.

Still need to add other color in the color toner pigment, etc.

Toner process mainly as follows: at present, the making craft of toner mainly;

Wet;

Or;

Dry;

Two methods of production.

Printer toner according to different requirements, the carbon powder production to develop in the direction of refinement, color and high speed.

Carbon powder manufacturing mainly adopts FenSuiFa and polymerization.

Carbon powder polymerization is a kind of fine chemical toner technology, it includes suspension polymerization, emulsion polymerization, detail capsule, dispersion polymerization, compression polymerization, chemical pieces.

Wet: solvent (

Benzene class)> resin grinding mill (

Grinding machine)

Dispersed pigments (

Or paint)

Heating mixing spray drying to precipitate into finished products of powder.

Dry: resin, pigments and other blend of roller, mixing, hammer crusher, jet mill, grading, finished product.

Custom message

![[Installation] teaches you how to properly install the fixing film](https://img80002719.weyesimg.com/uploads/ascendimage.com/images/15647364798527.jpg?imageView2/2/w/1920/q/75/format/webp)