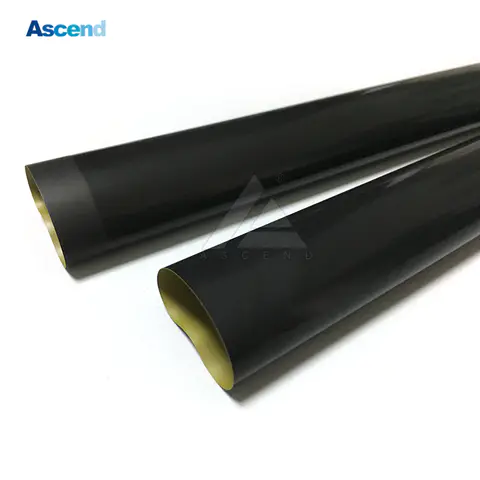

Fixing film is a film of special high temperature resistant materials used by copiers and printers for fixing during copying or printing. Fixing is the process of fixing unstable, erasable toner images on copy paper to paper. After the component is heated, the toner is melted, and then penetrates into the deep layer of paper fiber, making the effect of copying or printing more stable, firm and clear.

ASCEND is the pioneer who researched and developmented manufacture in China. also the leader in big size fixing Belt, we got a good reputation at home and aboard.

-

Ricoh MPC3503 Fuser Film SleeveInquire

Ricoh MPC3503 Fuser Film SleeveInquire -

Ricoh 8110 Fuser BeltInquire

Ricoh 8110 Fuser BeltInquire -

Fuser Film Sleeve for Ricoh MPC4000Inquire

Fuser Film Sleeve for Ricoh MPC4000Inquire -

Ricoh MPC2051 Fuser Film SleeveInquire

Ricoh MPC2051 Fuser Film SleeveInquire -

Konica Minolta C1060 fuser film sleeveInquire

Konica Minolta C1060 fuser film sleeveInquire -

Fixing film Ricoh MPC3502Inquire

Fixing film Ricoh MPC3502Inquire -

Ricoh MP C8002 fuser film sleeveInquire

Ricoh MP C8002 fuser film sleeveInquire -

Fuser Film Sleeve Canon IR3380Inquire

Fuser Film Sleeve Canon IR3380Inquire -

Canon IR4025 Fuser Film SleeveInquire

Canon IR4025 Fuser Film SleeveInquire -

Fuser Film Sleeve for Canon IR2016J 2016 2020 copierInquire

Fuser Film Sleeve for Canon IR2016J 2016 2020 copierInquire -

IRC4580 fuser film sleeveInquire

IRC4580 fuser film sleeveInquire -

Canon 5910 Fixing filmInquire

Canon 5910 Fixing filmInquire -

IR7260 Fuser Film Sleeve for CanonInquire

IR7260 Fuser Film Sleeve for CanonInquire -

Fuser Film Sleeve for canon LBP9100Inquire

Fuser Film Sleeve for canon LBP9100Inquire -

Xerox DCC2270 Fuser Film SleeveInquire

Xerox DCC2270 Fuser Film SleeveInquire -

HP Fuser Film Sleeve 2035Inquire

HP Fuser Film Sleeve 2035Inquire -

HP M806 Fuser Film SleeveInquire

HP M806 Fuser Film SleeveInquire -

HP Fuser Film Sleeve 4015Inquire

HP Fuser Film Sleeve 4015Inquire -

HP 4250 Fuser Film SleeveInquire

HP 4250 Fuser Film SleeveInquire -

Konica Minolta C6500 Fuser BeltInquire

Konica Minolta C6500 Fuser BeltInquire

ABOUT US

Ascend Technology Co.,Ltd (Guangdong Private Technique Enterprise, Guangdong High Technology Enterprise, Foshan Eagle Enterprise) was established in 2006, with its sub-factory found in 1998—“Yibang Products Precision Factory”, is a leading manufacturer specializing in developing, designing and producing copier and printer parts & accessories. We have a factory workshop of more than 3,1000 square meters, more than 200 experienced workers, advanced machines & equipments, professional technicians and a excellent sale team. Having got the ISO9001-2000 standard and follow its strictly control system, ISQ14000 environment certification, we stipulate for a fitly quality control system to assure quality & stable products, best performance.

We now handle a wide range of products for most popular models in the market including Transfer Belt,Fuser Film sleeve/Belt, PCR, Lubrication bar, Cleaning web roller, Fuser, Transfer belt Assy, Pick-up Roller/Tire, Upper Fuser Roller, Lower Pressure Roller etc with have got the ROHS certification. Stick to the policy of “precise quality, favorable prices and offer good products & services to meet customer’s satisfaction”, we never stop improving our products. With our strong developing ability, experienced & professional staff and technicians and strictly management, we get good reputation all over the world and strongly stand well in the market by our good quality products.

Products like Fuser Film Sleeve, Primary Charge Roller that put into market in 2005 achieve good satisfaction by customers all around. We export all products to Asia, Europe, America, Middle East and will spread to more countries in future..We believe with our good products and strong developing ability, our products can be of your focus in ten yeas. We will try our utmost to meet the demanding market to be one of the leading manufacturers and suppliers in this OA field.

1. Overview

1) Place of origin: Guangdong, China (Mainland)

2) Minimum Order (MOQ): 1 Piece

3) Packaging: 1pcs / Carton; customized acceptable

4) Delivery Time: Within 3-5 Working Days

5) Shipment: DHL FEDEX TNT UPS EMS Bysea

6) Supply Ability: 8000 Pieces per Month

7) OEM/ODM: Acceptable

8) Main Materials:

9) Warranty: 1 year

2. Bussiness Type: Manufacturer

3. Factory Address: 601/602, Tian You Chuang Fu Building, Jian Ping NO.1 Road, Guicheng, Foshan, Guangdong, China

4. Product Types: Fuser Film Sleeve, Transfer Belt, Primary Charge Roller, Cleaning Web Roller, etc.

5. Product Features:

◪Resistance features, Durability, Excellent quality, Original new products, Excellent printing results.

◪Toner dysplastic, Suitable for more adequate adsorption of toner to the paper surface, the effect is outstanding, more with the printer copier use.

◪Color laser /copier transfer belt with the first font printing to the transfer belt, and then printed by the transfer belt to the paper.

◪It has excellent abrasion resistance and transcription.

6. Custom Process

01 PROVIDE SAMPLE FROM CUSTOMER

Technical department is responsible for the design and formulation of the drawing documents, material, process flow chart, technical operation guidebook development, technical specification conversion, design; and the relevant drawings and technical requirements, test specifications are sent to the customer for confirmation.

02 SOLUTION&MANUFACTURING

DESIGN AND PRODUCTION

Technical department carries out the design and production of molds, tooling and inspection tools, and at the same time carries out the debugging of molds and tooling.

DRAWING EVALUATION

Material control department is responsible for evaluating the self-production or outsourcing processing according to the drawings provided by the technical department, and promptly consulting with the manufacturers, and subcontracting the parts or processes that the company cannot manufacture; implementing the parts and billet procurement cycle and tracking implementation

VERIFICATION PRODUCT

Production department is responsible for the trial production, verifying the conformity of the products, molds, tooling and tools, process parameters, and the correctness of the process route; number, date, process number, process name, number of roads transferred, waste of the material, operator , the number of completions, etc.

EXAMINATION

QC department process inspection carries out inspections on the new product production process, and conducts random inspection or full inspection on the new product finished products. In the inspection, it was found that the drawings were not met, and the project engineers were given timely feedback.

PROOFING

Proofing

OUTPUT

Sample output (Modification and confirmation).

PRODUCTION

Mass production be launched when samples approved by customers.

03 MASS PRODUCTION

Step 1 Extrusion

Step 2 Rough grinding

Step 3 Fine grinding

Step 4 Cleaning 1&2

Step 5 Resistance detection

Step 6 Packing

Step 7 Transportation

04 AFTER SALES / FEEDBACK

7. FOB Port: Guangdong

8. Quality Control:

Preproduction samples will be available before production

First Product Inspection

In-process Inspection

Preshipment Inspection

Container loading Inspection

9. Main Markets:

Asia

AustralasiaCentral

South AmericaMid East

Africa