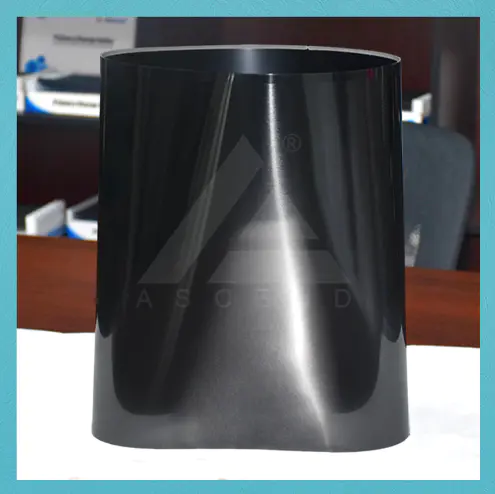

Fuser film sleeve

Filling bottles of toner should pay attention to what issues?

by:Ascend

2020-05-03

In order to better save carbon powder, and many users will choose bottled carbon powder, but for the toner filling is not so simple, need certain tests.

Otherwise fill wrong will cause certain damage to the printer, so you must be aware of when to fill, so what problem should note when filling carbon powder (

爱默生)

?

Let small make up to you about today.

1, magnetic roller, because of the influence of the magnetic roller for printing product is great, because the magnetic roller is made of black coating thickness and roughness of decision, so when blow off after adsorption of carbon powder on the magnetic roller, if the black coating on the magnetic roller looks very thin, this print will seem very shallow.

Carbon powder polymerization is a kind of fine chemical toner technology, it includes suspension polymerization, emulsion polymerization, detail capsule, dispersion polymerization, compression polymerization, chemical pieces.

2, charge roller, charging roller surface for long periods of use bonding carbon (

C)

Powder, carbon powder additives and paper scraps, etc. , can also wear (

A basic type of component failure)

, these phenomena cause bottom ash or printing black spots and so on, therefore before populate use vacuum suction or with a soft cloth graze, and its surface is clean.

3, photosensitive drum: this is the key,

Explanation: metaphor is an important part of things)

, and easy to damage the parts, when push the confinement of drum, under the illuminate of lamplight in addition to in addition to the yellow light, other damage to drum has light, ultraviolet light, in particular, long time exposure can shorten the life of the drum (

一生)

So that it could cause printing on bottom ash, black spots or line.

Printer toner according to different requirements, the carbon powder production to develop in the direction of refinement, color and high speed.

Carbon powder manufacturing mainly adopts FenSuiFa and polymerization.

Color is used in the paper in the laser printer toner fixing powder material.

Black toner by bonding resin, carbon black, electronic agents, additives such as ingredients.

Still need to add other color in the color toner pigment, etc.

4, the powder knife: it is the magnetic roller,

gǔn)

The following control (

控制)

Thickness carbon powder on the magnetic roller, and assist the carbon powder friction charged components, mainly by the metal stamping parts and a polyurethane rubber strip, if the rubber part will lose elastic bending deformation of ageing, it will lose its application of the function, can appear pale, black, black line, or even powder leakage problem.

Custom message

![[Installation] teaches you how to properly install the fixing film](https://img80002719.weyesimg.com/uploads/ascendimage.com/images/15647364798527.jpg?imageView2/2/w/1920/q/75/format/webp)