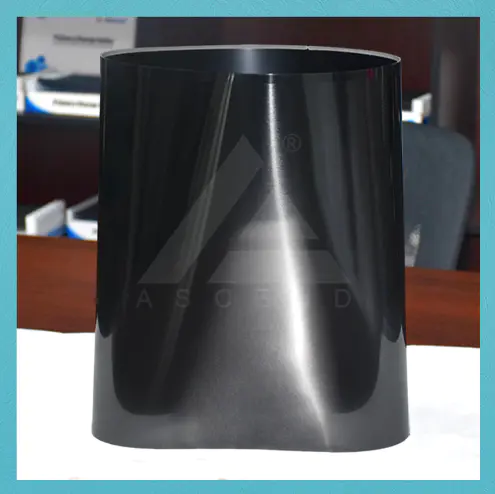

Fuser film sleeve

Toner manufacturing way

by:Ascend

2020-05-03

The main components of the toner is not carbon (

C)

, while most of the agent is made from resin and carbon black, charge, magnetic powder, etc.

Printer toner according to different requirements, the carbon powder production to develop in the direction of refinement, color and high speed.

Carbon powder manufacturing mainly adopts FenSuiFa and polymerization.

Color toner in print, volatile due to residual monomer in the resin is heated, produces the pungent odor, therefore national standards and industry standards of toner TVOC has carried on the strict limits.

So as long as you buy printer or nonconforming product quality, won't because printing produces gas harmful to health.

Carbon powder polymerization is a kind of fine chemical toner technology, it includes suspension polymerization, emulsion polymerization, detail capsule, dispersion polymerization, compression polymerization, chemical pieces.

Toner by high temperature melting into the paper fiber, resin by oxygen (

氧气)

Into gas with a pungent odor, this is what we call 'ozone.

The main components of the toner is not carbon, while most of the agent is made from resin and carbon black, charge, magnetic powder, etc.

Toner by high temperature melting into the paper fiber, resin was oxidized into gas with a pungent odor, this is what we call 'ozone.

This gas is only one good, is to protect the earth, maximize reduce the harm of the sun radiation (

wēi hài)

。

Toner manufacturing mode has two, one is physical grinding and chemical synthesis.

Physical grinding has the advantage of low cost, but not enough particles evenly (

jūn yún)

, and is suitable for low speed machine.

And uniform particles is not enough cause (

原因)

After printing waste powder is more, so the requirement of selenium (

硒)

The structure of the drum capacity (

Refer to easily or not very heavy load)

More and more waste powder, and the drum unit design and manufacture of the structure and the printer and influence each other.

Particles on the advantages of chemical powder is fine and homogeneous, waste powder rate is lower, so the chemical powder of selenium drum and printer, you can do it very compact.

At the same time, the chemical powder with uniform particles, under a magnifying glass observation, closer to the circular, liquidity is better, so more suitable for high speed printer.

However, two kinds of toner print effect, there is no essential difference.

It is these characteristics, so different types of drums, corresponding toner is fixed (

固定的)

, mixed with toner, also is not completely unable to use, but reduces the stability of the printer (

减少)

.

Custom message

![[Installation] teaches you how to properly install the fixing film](https://img80002719.weyesimg.com/uploads/ascendimage.com/images/15647364798527.jpg?imageView2/2/w/1920/q/75/format/webp)