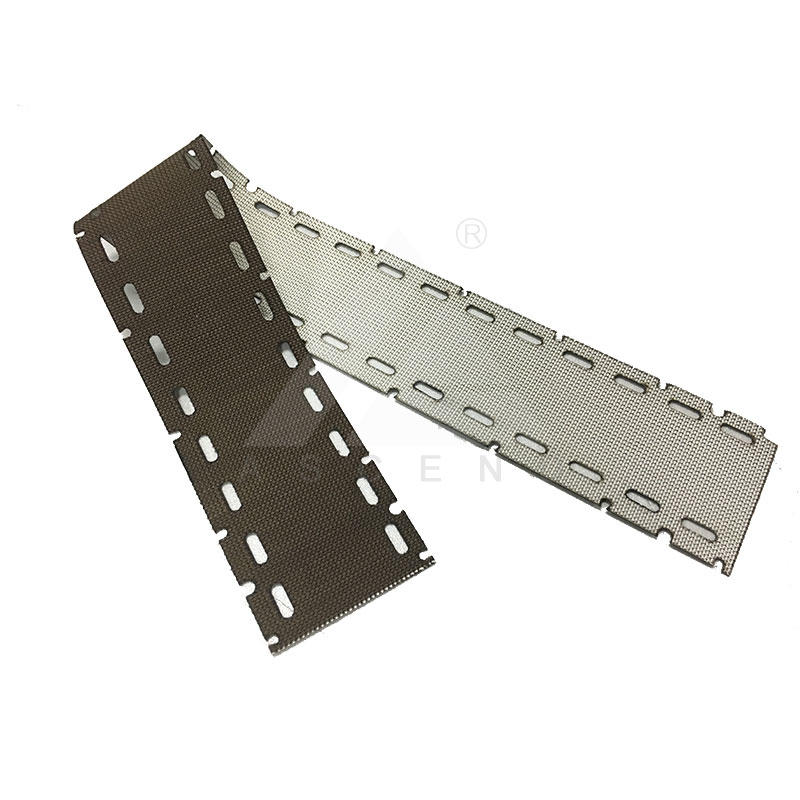

Teflon Sheet

Effect:

1. Used at low temperature - 196 C, high temperature between 350 C, with weather resistance and aging resistance. 2. Non-adherence: It is not easy to adhere to any substance.

3. Chemical corrosion resistance, corrosion resistance to strong acid, alkali, aqua regia and various organic solvents.

4. Low friction coefficient (0.05-0.1) is the best choice for oil-free self-lubrication. 5. The transmittance is 6-13%.

6. It has high insulation performance (dielectric constant is small: 2.6, tangent below 0.0025), anti-ultraviolet and anti-static.

7. Good dimensional stability (elongation coefficient less than 5) and high strength. It has good mechanical properties.

8. Drug resistance and non-toxicity. It can tolerate almost all medicines. 9. Fire and flame retardant.

Characteristic:

After practical application, if placed at 250 C for 200 days continuously, not only the strength will not decrease, but also the weight will not decrease. When placed at 350 C for 120 hours, the weight will only decrease by about 0.6%. When placed at - 180 C, the crack will not occur and the original softness will be maintained